Creighton Rock Drill Opens New Branch in Lévis , Quebec

We are thrilled to announce the opening of a new CRD location, as of October 1st, 2020. Thanks to the efforts of everyone in Quebec we were able to open […]

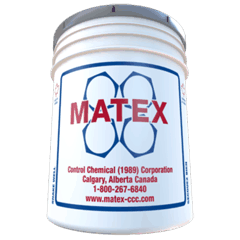

Environmentally Safe Drilling Fluids

Various construction sites such as building bridges, sea walls, high rise buildings, airports, and seaports all attract the public’s environmental eye. Environmental awareness has become more and more apparent and […]

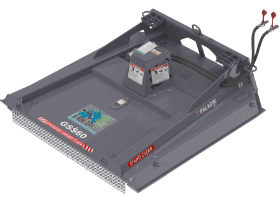

Drum Cutters – always grinding

Cutter-Heads, An Attachment Recommended For Every Crew! CRD is a single-source provider of quality made drum cutter attachments across various specs. we also provide replacement parts and service overhaul your […]

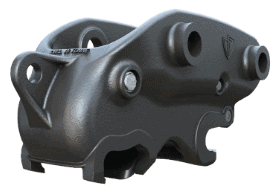

Mining Teeth Reviews – Black Cat Wear Parts’ RV Series

A review of the workhorse from Black Cat Wear Parts’ the RV series of Mining teeth and adapters. Featured here is the RV550LD, which stands at 78lbs as new, made for large […]

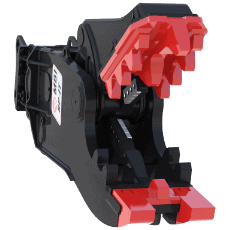

Combi introduces the new C-Rex R50 Teeth System

The C-Rex line up of GET systems is designed to deliver across terrains. Quality Swedish steel and enough wear material to get you through the project keeps operational costs down! […]

Custom Wear Solutions – Asphalt Plant Wear Liners

CRD provides custom wear solutions for your specific industrial needs and recently, we worked with the Miller Asphalt Plant in Port Colborne, Ontario who were looking to refurbish their drag […]

Covid-19 update for our customers and suppliers

March 24, 2020 To: All our customers and suppliers The COVID-19 situation has continued to rapidly evolve, and increased measures have been announced by the federal and the provincial governments. […]