The JOMA 6000 is the best way to decrease road marker wear, vibration, noise, and vehicle maintenance while more effectively removing snow and ice with less salt. That sounds like a lot of promises but the Joma 6000 delivers on all of them and on top of all that it is a cost-effective blade system for high-speed plowing.

Black Cat Wear Parts

THE REVOLUTIONARY JOMA 6000

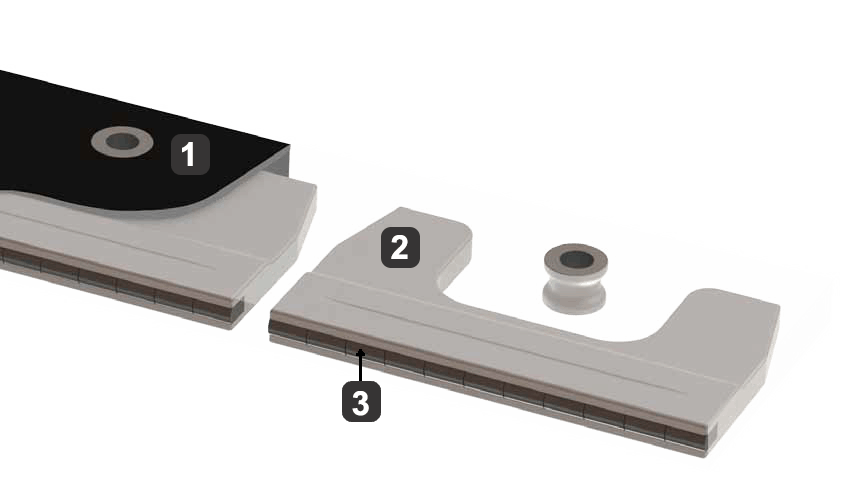

The JOMA 6000 blade is a unique design. It incorporates tungsten carbide inserts brazed into specially profiled steel segments in a rubber encasing. The result is dramatically superior life when compared to existing carbide-insert blades. There are numerous other benefits that are sure to increase the availability of your plow and reduce costs related to winter highway maintenance.

- Dramatic wear life improvement.

- Diminished vibration and noise.

- Reduced operator fatigue due to vibration and noise.

- Improved highway safety due to cleaner roads.

- Reduced sand and salt consumption.

- Decreased highway marking wear.

Application

The “JOMA 6000” is made in 3 and 4 lengths. These lengths can combine to fit most front-mounted or under-body plows. It is approximately 3/4 thick and 6 wide. For maximum oscillation, the mounting bushings are spaced at 12 centers and are adaptable to any standard highway punched (3,3,12 ) plow. For other applications such as 8 centers, an adapter blade is necessary. It will have your plow spacing on the top row of holes and holes spaced at 12”. With equal spacing at either end on the bottom. The adapter blade can be an existing steel or carbide blade, or a steel adapter designed specifically for mounting purposes only.

Longer Wear Life

The fact that there is no metal to metal contact between the blade and the plow allows the blade to absorb shock transmitted from the road surface. This shock-absorbing feature protects the insert from severe impact resulting in longer insert life and therefore longer wear life.

Minimized Vibration

Because the “JOMA 6000” is mounted by means of a Bushed Rubber mounting, there is no metal to metal contact between the blade and the plow. The rubber mount also absorbs most of the vibration that is normally transferred to the plow and truck. Vibration is the chief cause of many structural failures and also adds to operator fatigue. The removal of most of the vibration is sure to result in reduced maintenance costs and have a positive effect on operator comfort and safety.

Highway Markings

Another cost-saving feature of the “JOMA 6000” is the compatibility with highway lane markings. The rubber mounting helps to eliminate the chatter or bounce commonly found with a rigid blade. The rigidity of a steel blade combined with chatter contributes to the degradation of road markings. After several years of use in Sweden, the “JOMA 6000” has contributed to a substantial reduction in the cost of maintaining highway markings.

Noise Reduction

Noise is another cause of operator fatigue, not to mention the overall effect of noise pollution. Once again the rubber mount utilized by the “JOMA 6000” helps to dampen the sound produced by contact with the road, combined with any plow generated noise. The operator will readily notice this feature along with reduced vibration.

Cleaner Roads = Reduced Salt/Sand Consumption

Unlike a rigid steel blade, the “JOMA 6000” will form to the contour of the road. In doing so it cleans the road surface more effectively and therefore may require less salt or sand. This in itself could be a substantial saving, since salt and sand are one of the highest costs of most highways maintenance operations. A cleaner road surface should also add considerably to highway safety, potentially reducing accidents.