Sysbohr design and manufacture first-class drilling systems, tools, and accessories for the construction and geothermal industries. All products are manufactured in Fulda by Sysbohr and are distributed worldwide through an excellent distribution network. In-house specialists and consultants ensure that the requirements of the customer are fully met. Flexibility within the design and manufacture of products is one of the most important features.

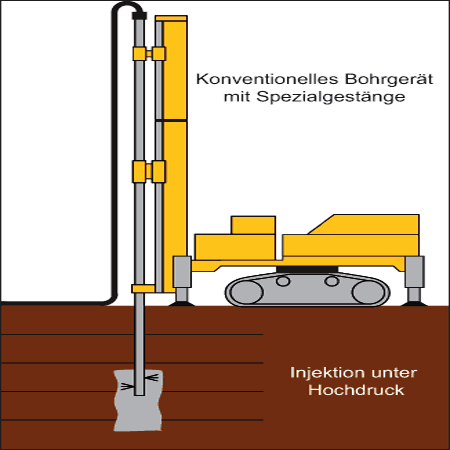

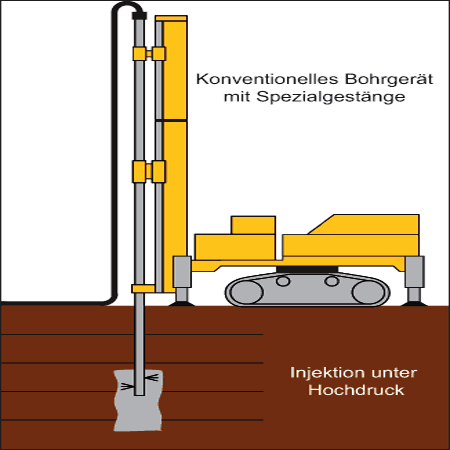

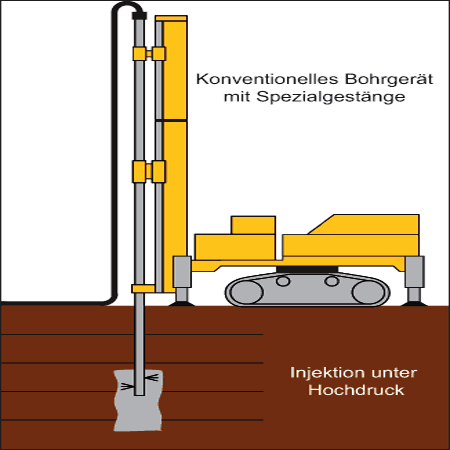

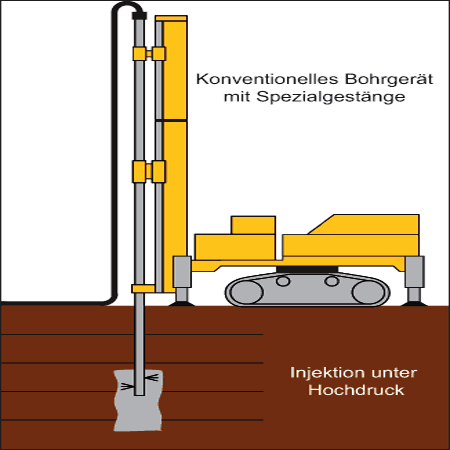

Jet Grouting Systems

Often used in ground stabilization projects. This system is suited for typical processes like ground consolidation and vertical shoring or lining. Jet grouting systems involves a cement suspension being injected via a jet nozzle into the surrounding soil wall-structure of the borehole, thereby eroding and mixing with the soil structure. This results in the formation of a subterranean grout column. Grout injection pressures fall in the range of 100 to 600 bar.

The drilling tools are specially developed to withstand the extreme pressures required. Having reached the final depth, the rods are slowly retracted at low rotational speeds, allowing the cement suspension or water to erode the surrounding bore-hole wall. By adding air to the process, the effective range of the jet stream can increase considerably. The drilling process is normally carried out with a rotary head, but for simplex jet grouting systems, a hydraulic drifter variant is available.

In the borehole, part of the soil erodes and then the flushing medium and cuttings is mixed with the cement slurry to form soilcrete.

Please see below the different jet grouting systems in detail.

Simplex Jet Grouting Systems

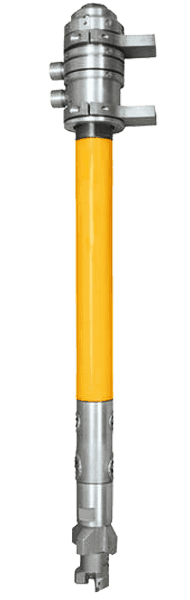

(HDI) D 88.9 - D 114.3 With Rotary Head And Hydraulic Chuck

This drilling system is especially used for grout injection to improve the ground conditions by i.e. consolidation, vertical shoring or lining slicing the soil structure by means of a jet of grout at pressures of 100 to 600 bar.

This drilling process is normally carried out using a hydraulic drifter and external flushing. The drilling tools are adapted for the extreme pressures required. Having reached the final depth, the rods will pull up slowly, allowing a jet of cement suspension to cut the surrounding ground. The corresponding nozzles are on the monitor. The boring are partly discharged with the flushing return movement, partly homogenized with cement. This complete drilling system D 88.9 is with different nozzle diameters and types of drill bits available.

It is suitable for soft ground conditions.

Simplex Jet Grouting Systems

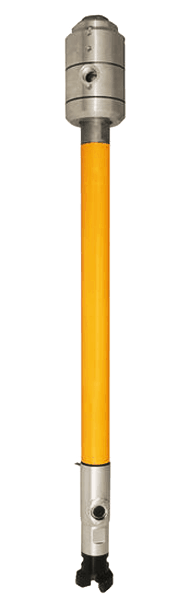

(HDI) D 88.9 With Hydraulic Drifter

This drilling system is especially used for grout injection to improve the ground conditions by i.e. consolidation, vertical shoring or lining slicing the soil structure by means of a jet of grout at pressures of 100 to 600 bar.

This drilling process is normally carried out using a hydraulic drifter and external flushing. The drilling tools are adapted for the extreme pressures required. Having reached the final depth, the rods will pull up slowly, allowing a jet of cement suspension to cut the surrounding ground. The corresponding nozzles are on the monitor. The boring are partly discharged with the flushing return movement, partly homogenized with cement.

This complete drilling system D 88.9 is with different nozzle diameters and types of drill bits available. It is suitable for soft ground conditions.

Duplex Jet Grouting Systems

D 76.1 - D 114.3 With Rotary Head And Hydraulic Chuck

These drilling systems are especially used for grout injection to improve the ground conditions by i.e. consolidation, vertical shoring or lining slicing the soil structure by means of a jet of grout at pressures of 100 to 600 bar.

This drilling process is normally carried out using a hydraulic drifter and external flushing. The drilling tools are adapted for the extreme pressures required. Having reached the final depth, the rods will pull up slowly, allowing a jet of cement suspension to cut the surrounding ground. The corresponding nozzles are on the monitor. The boring are partly discharged with the flushing return movement, partly homogenized with cement.

There are complete systems of D76.1 – D114.3 with different nozzle diameters and types of drill bits available. They are suitable for boulders and loamy grounds.

Triplex Jet Grouting Drilling System

D 114.3 - D 133 With Rotary Head And Hydraulic Chuck

Drilling systems like this are used to consolidate the overburden by grout injection. For this a jet pressure of 100 to 600 bar, with a flow rate of up to 400 m/s, is used to cut the soil structure.

The drilling process is achieved mainly with outer flushing. The drilling tools are adapted for the extreme pressures used. Having reached the final depth the rods will pull up with slowly, allowing a jet of cement suspension or water to cut the surrounding ground. By adding air, the effective reach of the jet can can increase considerably. There are separate channels in the rods for all flushing mediums like cement suspension, water and air. In the event of hitting boulders the cuttings are partly discharged with the flushing return, and partly homogenized with the cement.

There are complete systems of D 114.3 – D 133 with different nozzle diameters and types of drill bits available. They are suitable for boulders and loamy grounds.