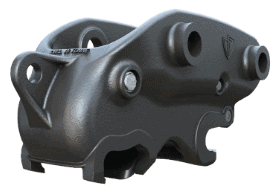

Coupler System for Excavators

The Best Coupler Systems For Excavators OilQuick Automatic Quick Couplers The ability to switch between attachments quickly and with ease is an edge worth upgrading to for any crew on […]

OilQuick Install

In the month of November our mechanics worked hand in hand with our customer Hard-Co Construction. Together CRD and Hard-Co worked on another multi day job of installing their new OilQuick […]

Demo Day #2!

Attachment Demo Day 2 and BBQ

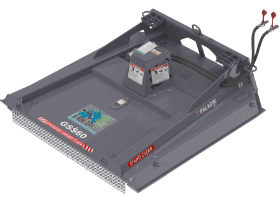

Demo Day

May 25 2016, Creighton Rock Drill partnered with Snow Brothers in Garth Snow’s shop in Erin Ontario to have a small demo showcasing the Oilquick Automatic Quick Coupler and a number of different attachments.These attachments […]

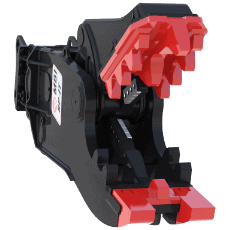

10 reasons why you need an OilQuick

Change the way you change your attachments. Become attached with the quickest, most efficient and simplest way of changing your hydraulics without any wasted time or effort.