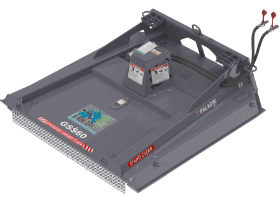

TUFFSTUDDS Wear Protection System is a cost-effective answer to protect equipment. Increasing performance and service life against severe wear and abrasion on equipment for mining, earthmoving and related industries.

TUFFSTUDDS

Abrasion Protection For Mining And Earth Moving Equipments

TUFFSTUDDS are chromium carbide-laden, wear-resistant alloy studs that are applied onto alloy castings or plates. In most applications the applied pattern becomes embedded with mineral debris causing a dead bed effect over 70% of the area that enhances wear protection.

The TUFFSTUDDS Wear Protection System has proven to be an outstanding performer in the roughest environments.

A Reliable Process, Simple To Apply

Apply TUFFSTUDDS with a stud welding system that employs a stud gun powered by a transformer/rectifier with solid-state weld timing and amperage control. For field applications requiring maximum portability, an AC generator with a minimum capacity of 85 kW can power the DC welding system. Each TUFFSTUDD takes only 0.6 to 1.2 seconds of arc time to apply. Simply load a TUFFSTUDD and a ceramic arc shield (ferrule) into the stud welding gun, position on the work surface, and pull the trigger.

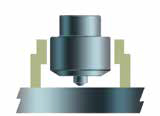

The TUFFSTUDDS Stud Welding Process(Four Steps)

- Position a TUFFSTUDD in contact with the work surface.

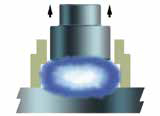

- The operator pulls the welding gun trigger, initiating the welding arc and automatically lifting the stud.

- Main welding current melts a portion of the stud and work surface. Within a second, the TUFFSTUDD plunges into the molten pool.

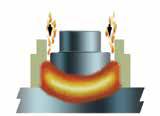

- Ceramic arc shield (ferrule) retains the molten metal in the weld area for maximum strength and safety. And the TUFFSTUDD is metallurgic-ally bonded to the work surface at the weld interface.

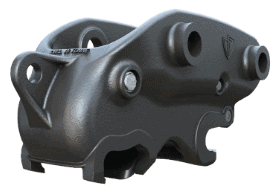

Stud Welding Equipment

The application of TUFFSTUDDS Wear Protection System is safe, reliable and easily applied using equipment designed for the stud welding process. Our stud welding equipment package is fully featured. Whether in your facility or at the job site, it’ll provide many years of dependable and trouble-free service. Easy operation and low maintenance costs.

The TS-1900 is a fully regulated welding power supply available in single or dual gun versions. The rectifier power source is constant current – variable voltage. A setup mode allows adjustment of weld time and current prior to welding. Which is shown on the front panel digital meters. A specially designed electronic gun control circuit has been built into the system. If a fault condition occurs as a result of a shorted gun solenoid or a faulty control cable, the circuit will prevent gun re-triggering. Thus preventing damage to the circuit board. Diesel driven field systems are available upon request.

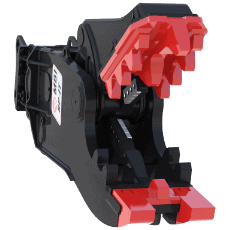

Heavy Duty Stud Welding Gun is a shaped-to-the-hand, semi-automatic heavy duty stud welding tool. It is capable of welding any size TUFFSTUDD® with an easy changeover of chunks, ferrule grips and foot pieces. Included are the standard legs, foot piece and gun cable (whip lead), combo weld/control and ground cables.