C20 Darda Rock-splitter Review

Putting The C20 To The Test McFadyen’s Stone Quarry, Located In Huntsville, Ontario, Is Renowned For The Exquisite Granite It Produces For The Homes And Cottages Of Southern Ontario. Every […]

New Distributor in Sudbury Mining Market

BREAKER TECHNOLOGY APPOINTS NEW DISTRIBUTOR IN SUDBURY MINING MARKET Thornbury, Ontario, July 11, 2017: Breaker Technology (BTI), the world-leading manufacturer of rockbreaking technology, and Creighton Rock Drill Ltd., an industry-leading Eastern Ontario […]

Crack Rock Demolition: Customer Testimonial

Crack Rock Demolition is the fastest, most powerful and economical expansive controlled demolition agent of its kind. It is made of a safe, non-toxic powdered mixture of natural minerals. When mixed […]

East Coast Move

CRD Nova Scotia Office Change Creighton Rock Drill Branches are located throughout Eastern Canada in some of the major cities. These access points allow us to better serve all of our […]

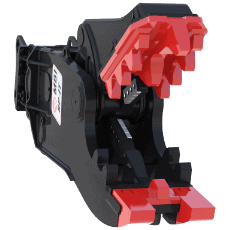

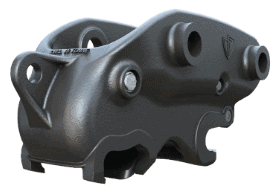

OilQuick Install

In the month of November our mechanics worked hand in hand with our customer Hard-Co Construction. Together CRD and Hard-Co worked on another multi day job of installing their new OilQuick […]

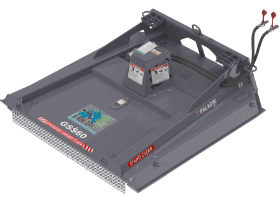

C-REX: King of Wear Parts

Combi’s newest is called the C-REX Tooth System that is produced in Sweden. This newly developed system has been put through extensive testing. The system was used in Europe in […]

CRD’s Instagram Account

Creighton Rock Drill Ltd has created an Instagram account where we will be posting a variety of different content! Including new products, pictures from trade shows, as well as our […]

New Chat Function!

New to our CRD website is the chat function where we will have live representatives to assist you with any questions you may have. Whether it’s a quick question about how a […]