Mantovanibenne is a company specialized in the design, production, and marketing of equipment for businesses in the earthmoving and demolition-recycling sectors. Each model of MBI Demolition Recycling is the result of advanced technological research. Ensuring high-quality standards, maximum-level productivity and sturdiness. Truly a guarantee of a safe investment over time.

MBI Demolition Recycling

Crusher CR

The Crusher CR gives the greatest efficiency and precision, thanks to the latest technological advances. Through 10 years of experience, Mantovanibenne has produced high-performance crushers.

Only the CR2 model has a unique hydraulic cylinder. Rotation enables precise and effective tool positioning. The 360° rotation can be mechanical on all ranges or hydraulic starting from 1450 kg models. All models are fitted with rebar-cutting blades.

| Model | CR2 | CR4 | CR5 | CR5R | CR15R | CR20R | CR26R | CR40R | CR60R | CR80R | CR100R | CR120R |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Excavator Weight (ton) | 03-05 | 03-06 | 06-10 | 07-11 | 16-20 | 21-26 | 27-35 | 45-55 | 60-70 | 75-95 | 100-120 | 120-140 |

| Tool Weight (kg) | 240 | 320 | 530 | 630 | 1600 | 2100 | 2800 | 4720 | 6250 | 8250 | 11000 | 12000 |

| Opening (mm) | 360/0 | 440/0 | 450/0 | 450/0 | 800/0 | 1050/0 | 1100/0 | 1350/0 | 1580/0 | 1800/0 | 2050/0 | 2310/320 |

Combined Crusher CC

The Combined Crusher CC has a union of powerful cylinders and a twin pin system grants huge breaking and cutting force. The unique design of the jaws incorporates shaped shear blades. These blades, together with the cutting guide, give the CC incredible cutting power. Interchangeable teeth and blades make upkeep operations easy and quick to keep the tool at full efficiency. The speed Valve reduces opening and closing time, boosting productivity.

| Model | CC25R | CC35R | CC65R | CC90R |

|---|---|---|---|---|

| Excavator Weight (ton) | 25-30 | 30-40 | 60-70 | 75-95 |

| Tool Weight (kg) | 2500 | 3500 | 6650 | 9500 |

| Opening (Max/Min)(mm) | 1000/0 | 1100/0 | 1525/0 | 1750/0 |

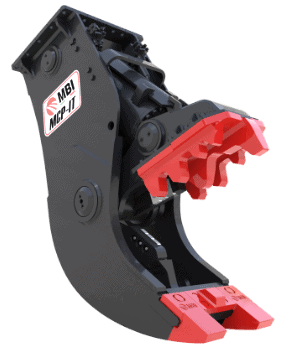

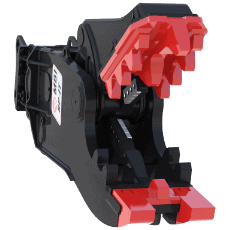

Fixed Pulverizer MCP-IT

The Fixed Pulverizer MCP-IT fixed head pulverizer is the ideal tool for secondary demolition on the ground. Its interchangeable plates have become a landmark in the industry and are designed to grant high productivity and easy maintenance. Its principal job is to crush concrete in order to separate the metal reinforcing bars.

| Model | MCP600-IT | MCP800-IT | MCP910-IT | MCP1000-IT | MCP1300-IT |

|---|---|---|---|---|---|

| Excavator Weight (ton) | 11-18 | 18-27 | 28-38 | 39-50 | 60-90 |

| Tool Weight (kg) | 1050 | 2200 | 3100 | 4200 | 8000 |

| Opening (mm) | 620 | 830 | 1000 | 1150 | 1300 |

Rotating Pulverizer RP–IT

The Rotating Pulverizer RP – IT has 360° rotation that makes a particularly accurate demolition tool for complete or partial building demolition. The RP range is fitted with a power valve to give maximum power when required and increase cycle times when no load is applied. New for this range is the tooth system in the jaw, the most robust in its class. The plate system can be changed quickly and easily. Thus minimizing machinery downtime, optimizing productivity.

| MODEL | RP10-IT | RP16-IT | RP20-IT | RP30-IT | RP40-IT | RP50-IT | RP80-IT |

|---|---|---|---|---|---|---|---|

| Excavator Weight (ton) | 10-18 | 16-20 | 18-26 | 26-32 | 32-45 | 45-60 | 60-90 |

| Tool Weight (kg) | 1100 | 1690 | 2000 | 2850 | 4100 | 5200 | 8200 |

| Opening (mm) | 580 | 700 | 750 | 900 | 1000 | 1100 | 1250 |

Shear Eagle III SH

The all-new Shear Eagle III SH through increased power, new jaw geometry, and new blade designs. All Eagle III blades can be changed quickly and easily. This reduces machinery downtime and improves productivity. The EAGLE III range is all fitted with power valves to maximize cycle times and provide maximum effort when needed.

| Models | SH250R | SH320R | SH490R | SH600R | SH800R | SH1500R | SH2200R |

|---|---|---|---|---|---|---|---|

| Excavator Weight (tons) | 24-29 | 30-40 | 45-55 | 55-70 | 75-85 | 120-170 | 170-300 |

| Shear Weight (kg) | 2.600 | 3.300 | 5.150 | 6.360 | 8.700 | 15.000 | 22.000 |

Multisystem MS

The Multisystem MS is a twin-cylinder main body that can be fitted with up to 6 different jaw configurations. The twin-cylinder formation ensures that it’s among the most powerful on the market. Efficient on high-reach demolition equipment gives excellent visibility for the operator. All models are equipped with speed power valves, giving the best cycle times, and ultimately maximum power when needed. All models have full and continuous 360° rotation, ensuring precise positioning of the equipment every time.

| Model | MS09R | MS15R | MS22R | MS28R | MS50R | MS60R | MS140R |

|---|---|---|---|---|---|---|---|

| Excavator Weight with MS Bucket Place (ton) | 10-15 | 16-20 | 21-27 | 28-40 | 45-55 | 60-70 | 120-160 |

| Excavator Weight with MS Stick Place (ton) | 7-10 | 10-15 | 12-18 | 15-24 | 28-38 | 30-50 | 80-120 |

| Hydraulic Working Pressure (bar) | 300-320 | 320-350 | 320-350 | 320-350 | 320-350 | 320-350 | 320-350 |

| Oil Flow (l/min) | 90-120 | 130-150 | 180-220 | 220-250 | 250-300 | 280-320 | 700-1000 |

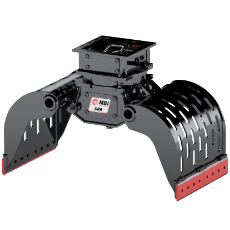

Grapple SGR

The Grapple SGR has been created for demolition work and waste sorting resulting in an efficient demolition recycling operation. The grapples are manufactured using the most modern steels combining strength, lightweight with excellent wear-resistant properties. The highest quality cylinders ensure perfect and regular open-close action. The 360° rotation, standard on all models, enables a precise and effective positing of the grapple. All grapples are fitted with reversible wear blades for maximum performance.

| Model | SGR200 | SGR300 | SGR450 | SGR600 | SGR850 | SGR1000 | SGR1100 | SGR1200 | SGR1500 | SGR1900 | SGR2500 | SGR2700 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Excavator Weight (ton) | 1.5-3 | 3-6 | 5-8 | 7-11 | 10-15 | 14-18 | 16-20 | 18-22 | 21-25 | 25-30 | 30-35 | 35-40 |

| Tool Weight (kg) | 180 | 320 | 565 | 750 | 860 | 1330 | 1400 | 1480 | 1570 | 2260 | 2520 | 2570 |

| Capacity (l) | 50 | 100 | 300 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 |

| Hydraulic Working Pressure (bar) | 200-250 | 200-250 | 200-250 | 250-300 | 300-320 | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 |

| Oil Flow (l/min) | 5-8 | 10-15 | 20-30 | 20-30 | 20-30 | 50-60 | 50-60 | 50-60 | 50-60 | 50-60 | 70-80 | 70-80 |

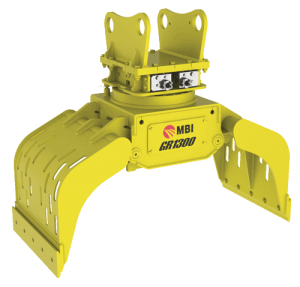

Grapple GR

The Grapple GR has been created for demolition work and waste sorting resulting in an efficient demolition recycling operation. The grapples are built using the most modern steels combining strength, lightweight with excellent wear-resistant properties. The highest quality cylinders ensure perfect and regular open-close action. The 360° rotation, standard on all models, enables a precise and effective positing of the grapple. All grapples are fitted with reversible wear blades for maximum performance.

| Model | SG450 | SG600 | SG850 | SG1000 | SG1100 | SG1200 | SG1500 | SG1900 | SG2500 | SG2700 |

|---|---|---|---|---|---|---|---|---|---|---|

| Excavator Weight (ton) | 5-8 | 7-11 | 10-15 | 14-18 | 16-20 | 18-22 | 21-25 | 25-30 | 30-35 | 35-40 |

| Tool Weight (kg) | 410 | 555 | 655 | 910 | 980 | 1055 | 1142 | 1720 | 1980 | 2030 |

| Capacity (l) | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 |

| Hydraulic Working Pressure (bar) | 200-250 | 250-300 | 300-320 | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 |

| Oil Flow (l/min) | 20-30 | 20-30 | 20-30 | 50-60 | 50-60 | 50-60 | 50-60 | 70-80 | 70-80 | 70-80 |

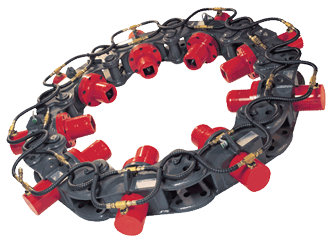

Pile Breaker PB

The Pile Breaker PB is powerful, accurate and, most of all, almost silent in its operation.

The modular design of the Pile Breakers enables them to be used on piles of various sizes from 300mm to 2000mm in diameter for the round piles, and 300mm to 750mm for the square piles. Providing the hydraulic flow and pressures are available, the Pile Breaker can be hung from a large variety of equipment, excavators, cranes, etc.

Side/Diameter Pile (mm) ± 10mm

Piles

| Model | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Excavator Weight (ton) | 10-15 | 10-15 | 10-15 | 10-15 | 10-15 | 15-20 | 15-20 | 15-20 | 15-20 | 15-20 | 15-20 |

| Elements (nr) | 6L | 6L | 7L | 7L | 7L | 8L | 8L | 8L | 9L | 9L | 9L |

| Tip Type | M | C | L | M | C | L | M | C | L | M | C |

| Tool Weight (kg) | 1000 | 1000 | 1160 | 1160 | 1160 | 1330 | 1330 | 1330 | 1490 | 1490 | 1490 |

| Hydraulic Working Pressure (bar) | 320-350 | 320-350 | 320-350 | 320-350 | 320-350 | 320-350 | 320-350 | 320-350 | 320-350 | 320-350 | 320-350 |

| Oil Flow (l/min) | 150 | 150 | 175 | 175 | 175 | 200 | 200 | 200 | 250 | 250 | 250 |

| Dimension H (mm) | 1700 | 1700 | 1900 | 1900 | 1900 | 2050 | 2050 | 2050 | 2200 | 2200 | 2200 |