The Astec hydraulic breaker design incorporates only two internal moving parts, offering reliability and long life. Designed to tackle construction, demolition, recycling, mining, and quarrying, the models range from 350 to 13,500 ft. lbs. classes. You can be assured of finding just the right capabilities. Call us today and you will be in high production breaking tomorrow.

Hydraulic Breakers

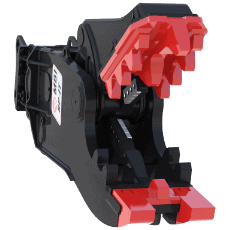

CX Series

Easy to Service

With fewer parts integrated into the design, servicing the

hydraulic hammer is both easy and less expensive

Low Operating Cost

High flow rates and low operating pressures minimize heat generation and hydraulic shock loading for smooth operation and maximum service life for both the carrier and hydraulic rock breaker

Operate in Varying Rock Conditions

Anti-blank fire on/off selector allows you to alternate modes when working in varying conditions (CX8 only)

Reduce Noise Levels

Boxed housing keeps the noise levels down, essential in high-density population areas

Optimize Production

Breaker-mounted manual high/low stroke selector valve

optimizes power and speed, giving you options

Configurations

Configured for today’s skid steers, mini excavators, and backhoes for efficient use of the carrier’s hydraulic circuit

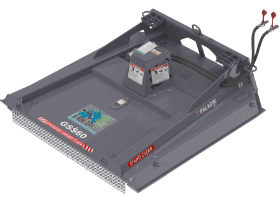

BX Series

Easy to Service

With fewer parts integrated into the design, servicing the

hydraulic hammer is both easy and less expensive

Low Operating Cost

High flow rates and low operating pressures minimize heat generation and hydraulic shock loading for smooth operation and maximum service life for both the carrier and breaker

Operate in Varying Conditions

Anti-blank fire on/off selector (BX10 – BX30) allows you to alternate modes when working in varying rock conditions

Extreme Duty and Wear Bar Kit Option

The extreme duty and wear bar kit offers additional protection against the wear and tear of your hydraulic rock breaker with a factory application of cast abrasion strips and a wear-resistant plate with rock claws

Reduce Noise Levels

Boxed housing keeps the noise levels down, essential in high-density population areas

Optimize Production

Hydraulic rock breaker-mounted manual stroke selector valve optimizes power and speed, giving you options for different applications

Auto-grease Options

The auto-grease system keeps your tool lubricated without the hassle of stopping your production cycle flow while delivering just the right amount of grease when it’s needed most. The system installs directly on the breaker

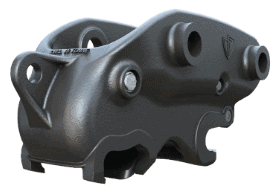

BXR Series

Extreme Impact Energy

The extra-long stroke pressure balanced piston, oil regeneration system, and button-nose piston design maximize the blow energy needed to break hard rock

Continuous Duty in Harsh Conditions

High-strength alloy plate steel with abrasion-resistant plate housing and heat-treated alloy pistons allows the rock breaker

to withstand the harshest conditions

High Operating Efficiency

The oil regeneration system increases BPMs (Beats Per Minute) without decreasing energy in hard material applications

Protection for Internal Components

Anti-blank fire on/off selector keeps the rock breaker from firing until tool force is applied, protecting your internal components from unnecessary damage

Optimize Production

Long/short stroke selector (manual or remote) optimizes power and speed, giving you options for different applications

Reduce Noise Levels

Boxed housing keeps the noise levels down, essential in high-density population areas

| Specification | BXR50C | BXR65C | BXR85C | BXR100C | BXR120C | BXR160C | BXR185C |

|---|---|---|---|---|---|---|---|

| Operating Pressure | 2,700 psi / 186 bar | 2,700 psi / 186 bar | 2,700 psi / 186 bar | 2,700 psi / 186 bar | 2,700 psi / 186 bar | 2,700 psi / 186 bar | 2,700 psi / 186 bar |

| Overall Length | 103 in / 2,622 mm | 112 in / 2,863 mm | 128 in / 3,241 mm | 134 in / 3,400 mm | 138 in / 3,500 mm | 155 in / 3,943 mm | 181 in / 4,590 mm |

| Exposed Tool Length | 25 in / 635 mm | 26.2 in / 665 mm | 29.3 in / 745 mm | 30.3 in / 770 mm | 31.9 in / 810 mm | 36.6 in / 930 mm | 36 in / 913 mm |

| Operating Weight | 4,200 lb / 1,910 kg | 4,860 lb / 2,200 kg | 6,500 lb / 2,950 kg | 7,800 lb / 3,540 kg | 9,200 lb / 4,170 kg | 12,100 lb / 5,490 kg | 7,100 kg / 15,660 lb |

| Tool Diameter | 5.5 in / 140 mm | 6 in / 150 mm | 6.3 in / 160 mm | 6.7 in / 170 mm | 7.1 in / 180 mm | 7.9 in / 200 mm | 8.7 in / 221 mm |

Specification BX10 BX15 BX20 BX30 BX40 Operating Pressure 2,000 psi / 140 bar 2,000 psi / 140 bar 2,300 psi / 160 bar 2,450 psi / 170 bar 2,450 psi / 170 bar Overall Length 71 in / 1,800 mm 78 in / 1,980 mm 88 in / 2,225 mm 97 in / 2,455 mm 109 in / 2,760 mm Exposed Tool Length 17.5 in / 445 mm 18.5 in / 465 mm 21.3 in / 438 mm 26.5 in / 668 mm 26.5 in / 668 mm Operating Weight 948 lb / 430 kg 1,355 lb / 615 kg 2,050 lb / 930 kg 2,668 lb / 1,210 kg 3,830 lb / 1,740 kg Tool Diameter 3.1 in / 78 mm 3.3 in / 85 mm 4.1 in / 105 mm 4.7 in / 120 mm 5.3 in / 135 mm

| Specification | CX4 | CX6 | CX8 |

|---|---|---|---|

| Operating Pressure | 1,710 psi / 120 bar | 2,000 psi / 140 bar | 2,000 psi / 140 bar |

| Overall Length | 53 in / 1,334 mm | 55 in / 1,408 mm | 64 in / 1,635 mm |

| Exposed Tool Length | 12.6 in / 321 mm | 13.5 in / 344 mm | 19.7 in / 500 mm |

| Operating Weight | 296 lb / 180 kg | 493 lb / 244 kg | 734 lb / 333 kg |

| Tool Diameter | 2.1 in / 53 mm | 2.4 in / 62 mm | 2.8 in / 70 mm |