WEAR SOLUTIONS

Creighton Rock Drill Ltd. specializes in quality part Wear Solutions offering abrasion-resistant materials to prolong the life of your equipment from companies with state-of-the-art Wear Resistant Products. We understand all Wear is not equal! with custom-cut wear-resistant steel from High-Alloy, Chromeweld®, 400/500 Hardox®, White-Iron & Manganese bases, the right solution across Abrasion, Impact or Corrosion Resistance scales can be found at CRD Creighton.

BLOCKS, EDGES AND PROFILES

Bruxite Wear Plates

Think hard steel that works for you. Bruxite lives and dies for maximum wear time and optimal protection. Run it hard ‘n’ tough and get the job done…Read More

Bruxite Wear Edges and Profiles

When you see wear edges and bars with buckets and heavy machinery, think Bruxite. Think hard steel that works for you. Bruxite lives and dies for maximum wear time and optimal protection…Read More

CHROMIUM CARBIDE WHITE IRON

CRD Grizzly Bars

Investment Protection

Standard sizes minimize customer cost vs. custom shapes.

Peaked profile offers longer wear life and greater material deflection. … Read More

CRD Wear Buttons & Donuts

Ideal for smaller areas requiring wear-resistant material.

Requires less welding time and material than conventional wear plate. … Read More

CRD Skid Bars

Far superior to standard Q & T wear plates offering greater wear life. Available in straight, herringbone, or domed shapes. … Read More

CRD Chocky Bars

Most popular for replacing hard-facing and clad plate.

Available with or without a notched backing plate.

Easy to cut and shape over contoured surfaces. … Read More

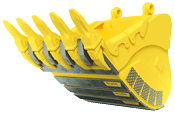

Bi-Struct 700BHN Bucket Shrouds

Wear solutions management including Lip Shrouds, Wing Shrouds, and Heel Shrouds…Read More

ABRASION AND WEAR PROTECTION

TUFFSTUDDS

Wear Protection System protects equipment cost-effectively, increasing efficiency and service life against severe wear and abrasion on equipment for mining, earthmoving and related industries. … Read More

Tri-Braze Dura-Plus

The next step in the evolution of abrasion and impact-resistant alloy steels. This patent-pending technology provides a combination of hardness, toughness, form-ability, and wear-ability that is unavailable in any other. … Read More

PIVOT WEAR / LUG WEAR SOLUTIONS

Expander Pin System

A permanent solution to lug wear, the expander system by Nord-Lock provides a cost-effective one-time solution to replace worn-out mountings without welding and line boring, field-tested, and proven to outlast any stock pivot lugs with over…Read More