Silent Demolition Agent

Crack Rock Demolition

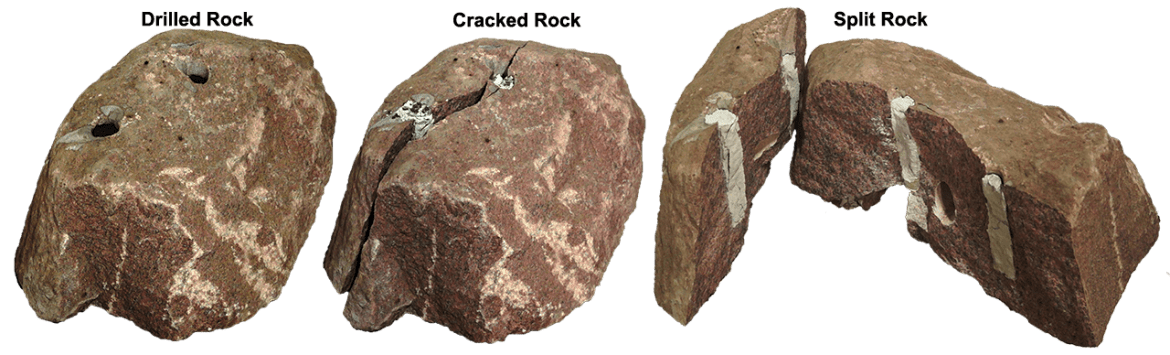

Crack Rock Or Concrete Using 3 Easy Steps

The Silent Demolition Agent by Crack Rock Demolition is the fastest, most powerful, and economically expansive controlled demolition agent of its kind. It is made of a safe, non-toxic powdered mixture of natural minerals. When mixed with water and poured into pre-drilled holes it will expand at an incredible force of over 20,000 PSI. Able to break any strength of rock or concrete.

APPLICATIONS

CONCRETE BREAKING

• Equipment pads.

• Retaining walls.

• Pillars.

• Beams.

• Foundations.

• Patios.

• Stair wells.

• Driveways.

• Roadwork.

ROCK BREAKING

• Boulder removal.

• Boulder breaking.

• Excavation.

• Trenching.

• Leveling.

• Tunneling.

QUARRY & MINING

• Granite.

• Marble.

• Limestone.

• Sandstone.

• Onyx.

BENEFITS

• Raise productivity.

• Increases safety.

• Cut labor costs.

• Reduces pollution.

• Decrease removal time.

• Safe, environmentally

friendly and gentle.

• Clean, efficient and

cost effective.

• Not explosive.

• Non impact.

• Non flammable.

• No special training,

equipment or licenses.

• Provides access to areas

where heavy plant or

explosives are prohibited.

• No transportation

restrictions.

• Eliminate noise.

• No vibrations,

flying rocks or

toxic vapors.

How to Use Silent Demolition Agent

Step 1 - Drill

- Wear your safety glasses, rubber gloves, dust-proof mask and have all equipment needed in place.

- Drill holes using a core drill, rock drill or compatible drill using a 1.5” diameter drill bit 8 to 16” apart. For harder rock and reinforced concrete hole spacing should be no more than 8” apart.

- Drill between 80 to 90% of the depth within the material needing to be cracked.

- Silent Demolition Agent slurry must have free space to expand into. Create a series of empty holes if required.

- For specific drill patterns refer to the Drill Guide on this bucket or our website.

Step 2 - Mix

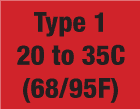

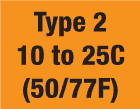

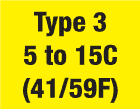

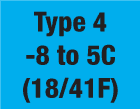

- Select the correct product type for your specific temperature range in the coloured blocks below.

- Pour 1.5 – 1.7 litres of clean cold water in a bucket and gradually add one bag (5Kg) of Silent Demolition Agent powder. Do not mix more than 2 bags (10Kg) at a time.

- Using a mixing paddle completely dissolve powder in water and stir into a slurry. Longer mixing times will likely cause blowout shoot.

Step 3 - Pour

- After drilling minimize water and residue left behind in the holes before using product.

- Within 10 minutes of mixing pour the product into the holes filling within to 1” from the top.

- Continuously pour the mixture into the holes one at a time to ensure no air gaps are trapped within.

- For horizontal and slant holes, insert a slightly smaller plastic pipe into the hole, and then fill the expansive slurry into the pipe slowly, withdrawing the pipe from the hole simultaneously then cap it.

- Do not leave any surplus mixture in the bucket use all remaining expansive mortar slurry.

- After the holes have been filled keep out of sunlight, cover with a tarp and do NOT look into the holes.

- For best results allow product to set for 24 hrs (product will continue to expand up to 48 hrs).

Results Of Crack Rock Demolition - Silent Demolition Agent