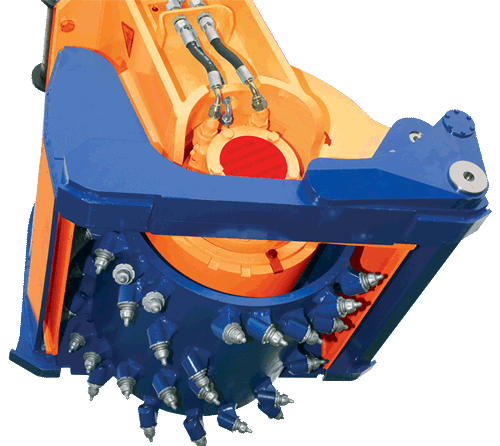

The KEMROC patch planer is designed to repair asphalt surfaces or to remove layers of concrete/screed. With eight models, there is a planer to fit all carriers in the 1 to 23 ton operating weight range. Depending on the material to be ground, different designs of drum and tooling can be fitted. Designed to achieve best performance and precision when removing materials. While offering low noise and less vibration. This is critical when working in sensitive environments. Kemroc consists of extremely robust spur gears driven by high torque hydraulic motors for the most challenging conditions with little to no risk of failure.

Kemroc Exactor Patch Planing Technology

FOR EXCAVATORS & BACKHOE MACHINES

Manufactured in Germany, The EX range of Kemroc Patch Planers is designed for the accurate planing of asphalt, concrete, and stone. The Exactor range consists of patch planers available in 4 sizes. Each suitable for use on excavators from 6 to 40 tons. Cutter drums for each machine will be available with a choice of tools and cutting widths.

Excavator Patch Planing works on horizontal, vertical, and inclined surfaces. As well as upside down to plane the roofs of tunnels. Patch Planers are ideally suited for the repair of asphalt surfaces. Including work requiring tight tolerances such as the removal of very small depths of contaminated concrete or screed floor surfaces.

To provide the best performance on a range of carrier vehicles, a choice of Exactor hydraulic motor specifications are available to suit each application. The mechanical, or optional hydraulic, system for depth control allows the cutting depth to be set at any figure from 0 to 8 ins, depending on model. If a suction device should be used to extract the cut material, a modified housing can be supplied specifically designed for this purpose.

Additional Features

- Standard cutting widths from 8 – 24 ins.

- High torque motors providing high productivity.

- Modular construction providing easily adjustable torque / rotation speed ratios.

- Exchangeable hydraulic motors.

- Heavy duty, wear resistant sliding frame.

- Continuous mechanical adjustment of cutting depth (hydraulic adjustment optional).

- Optimal positioning of the cutting tools for a smooth cutting action and cutting surface.

- high productivity and good quality cut edges.

- Optimum wear rates in asphalt, concrete and rock.

- Cutter wheels for narrow slots with max. depth of 7 ½ ins.